IEC60068-2-75 Universal spring impact hammer

Instrument

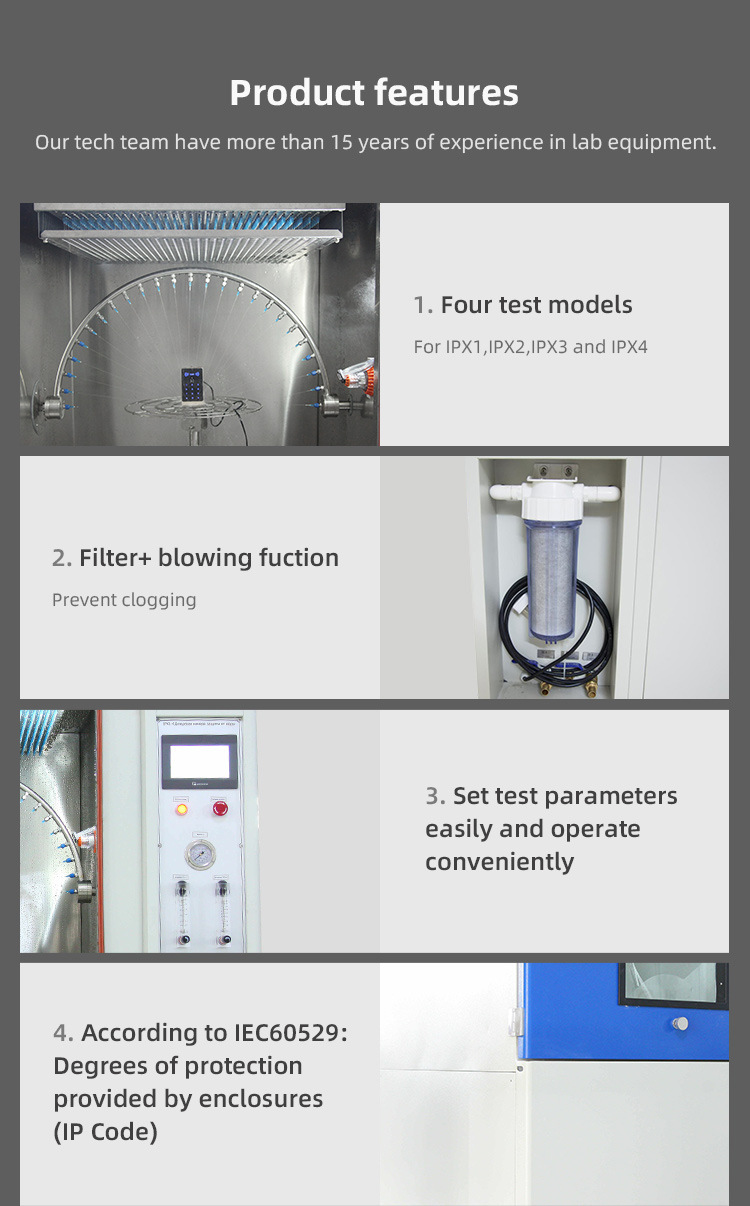

The instrument is designed to conform to IEC60068-2-75 and other commonly used standards in the market. All components are made to the specifications required by the standards. Hammers are available in single force selections or a Universal Spring Hammer that offers five selectable impact energies. Each hammer is delivered in a protective case with a calibration certificate.

Application

Impact Hammers are used to check the durability of enclosures for electrical appliances or other electronic products. If damage occurs from the Impact Hammer test, Accessibility Probes can be used to measure the extent or severity of the damage. The Impact Hammer simulates the mechanical impact to which electrical equipment may be subjected.

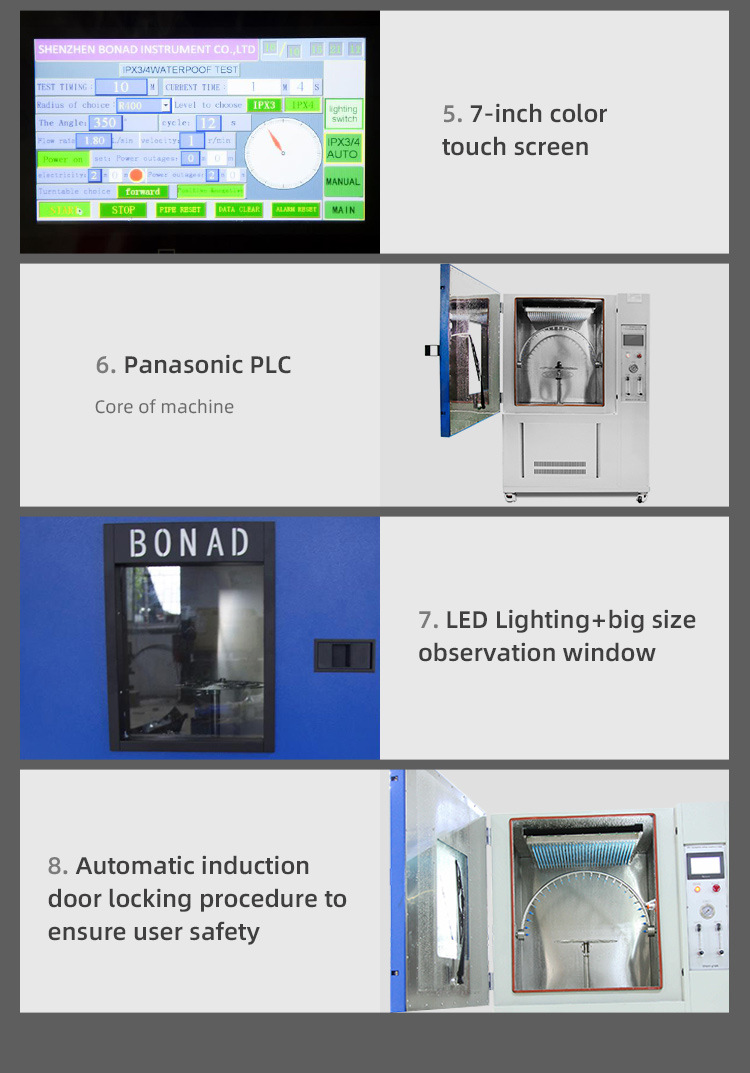

Features

Body (includes release mechanism and striking element guide) mass = 1250g

Striking element with cocking knob and hammer head, polyamide face with a radius of 10mm mass = 250g

Hardness of Hammer Head = R100 (Rockwell Hardness)

Release Cone: 60g, release pressure <10N

(Remark: Model SI-2026 2J Spring Hammer striking element mass = 500g, release pressure <20N, hammer head with radius of 25mm made of steel with a hardness of R80-85)

Conforms To

IEC60068-2-75, IEC60065, IEC60335-1, IEC60598-1, IEC60745-1, GB4706.1, GB8898,GB7000.1

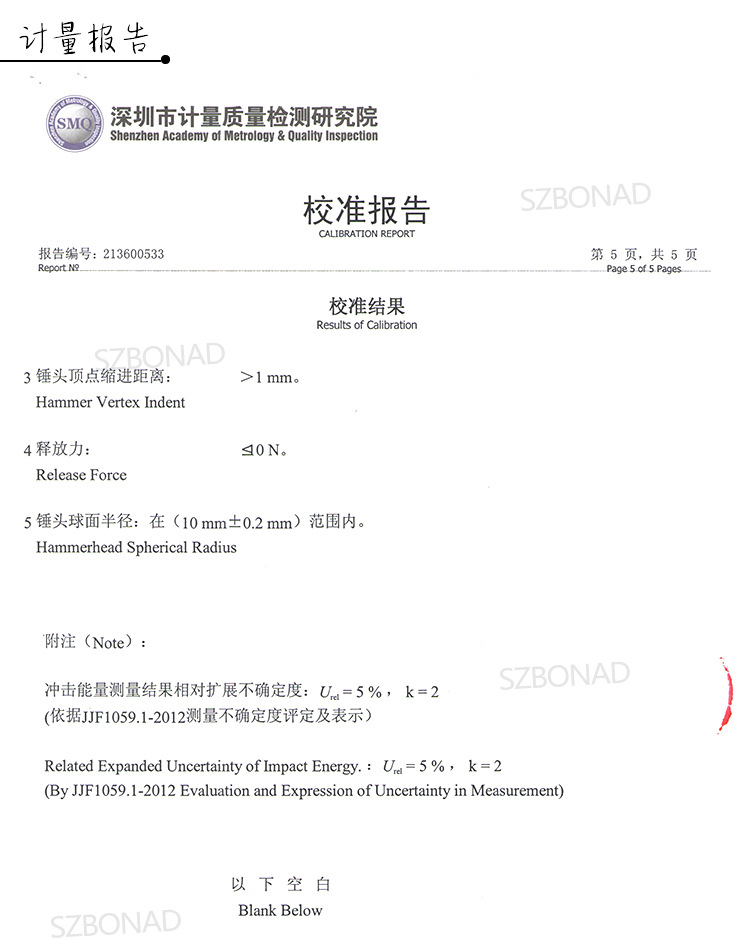

Calibration

Calibration from the third party institute, provide CNAS and ILAC certificate

Type

6 Types: Single energy Impact Hammer: 0.14J/0.20J/0.35J/0.50J/0.70J/1.0J

1 Type: Universal 6 energy Impact Hammer: 0.14J/0.20J/0.35J/0.50J/0.70J/1.0J/2.0J

|

Single Impact Energy

|

Error

|

|

0.14J

|

±0.014J

|

|

0.20J

|

±0.020J

|

|

0.35J

|

±0.03J

|

|

0.50J

|

±0.04J

|

|

0.70J

|

±0.05J

|

|

1.00J

|

±0.05J

|

|

2.00J

|

±0.10J

|

|