IEC60068-2-75 Spring impact hammer calibration test device

Model:BND-THJZ

Introduction to IEC60068-2-75 Spring Impact Hammer Calibration Equipment

The Spring Impact Hammer Calibrator, designed in accordance with IEC60068-2-75-1997 and GB2423.55-2006 standards, is an essential tool for ensuring the precision and reliability of spring-operated impact hammers. This calibration device is particularly beneficial for third-party testing organizations, national immigration departments, and appliance-related research institutes.

Superior Manufacturing and Design

Our calibration equipment boasts superior performance due to the use of specialized materials and advanced manufacturing processes for critical components. This results in exceptional accuracy and stability. The single-weight design of the device supports a wide range of calibration hammers from both domestic and international manufacturers.

Key Features of the Calibration Device

-

Calibration Procedure Guide: The device includes a comprehensive guide that provides step-by-step instructions for calibrating spring hammers. It outlines specific parameters such as force range and the number of impacts required during the calibration process.

-

Safety Features: Safety is paramount in the design of our calibration device. It incorporates safety enclosures, protective shields, and strict safety protocols to ensure operator protection and prevent accidents during the calibration process.

Importance of Regular Calibration

Regular calibration of spring impact hammers is crucial for maintaining their accuracy and reliability. A calibrated device ensures that hammers deliver consistent and repeatable impact forces, which is vital for accurately assessing product durability and impact resistance. By using a calibrated spring hammer, manufacturers and quality control departments can confidently rely on test results to make informed decisions regarding product design, material selection, and overall performance.

In summary, investing in a high-quality Spring Impact Hammer Calibrator not only enhances testing accuracy but also contributes significantly to product quality assurance. Whether you are a manufacturer or part of a quality control team, this device is indispensable for maintaining high standards in impact testing.

Technical parameters:

|

The actual accuracy

|

0.01J

|

|

Repeat accuracy

|

±0.01J

|

|

Maximum range

|

0-2J

|

|

Guide Groove Diameter

|

51mm

|

|

Pendulum Energy loss

|

<0.002J

|

|

Trigger Route

|

>30mm

|

|

Weight

|

1pcs

|

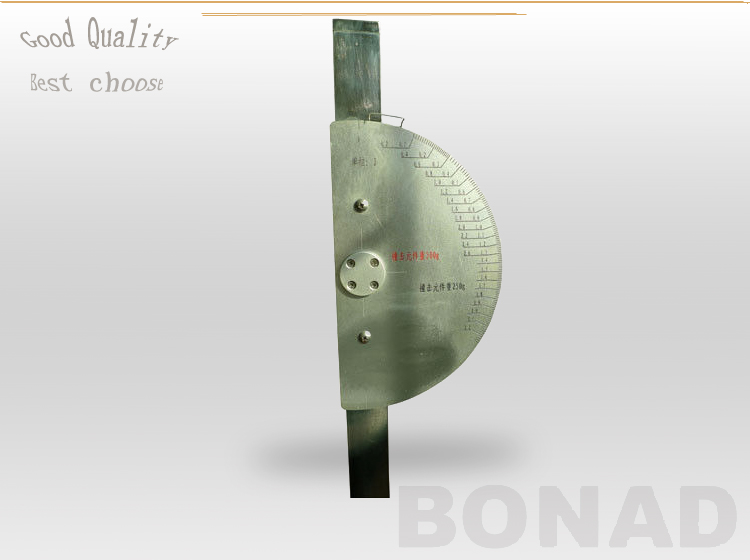

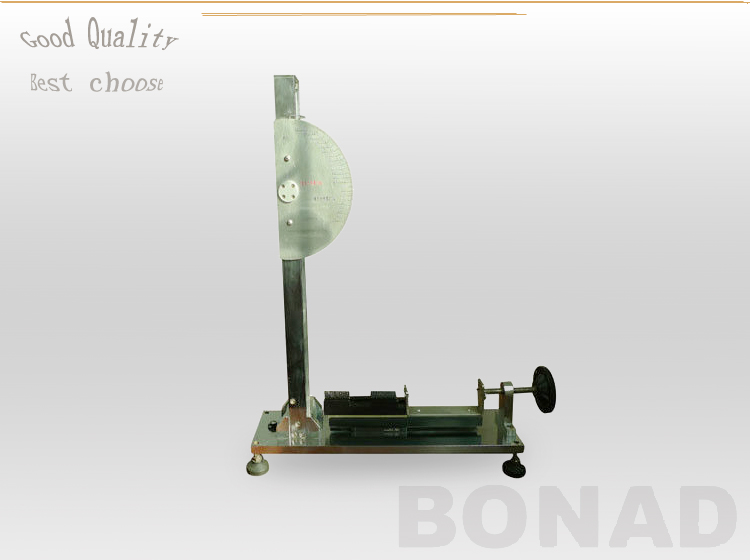

Picture show:

|